This type of personnel contamination can degrade product performance in the semiconductor and pharmaceutical industries and it can cause cross-infection between medical staff and patients in the healthcare industry for example.Ĭleanroom garments include boots, shoes, aprons, beard covers, bouffant caps, coveralls, face masks, frocks/lab coats, gowns, glove and finger cots, hairnets, hoods, sleeves and shoe covers. The cleanroom clothing itself must not release particles or fibers to prevent contamination of the environment by personnel.

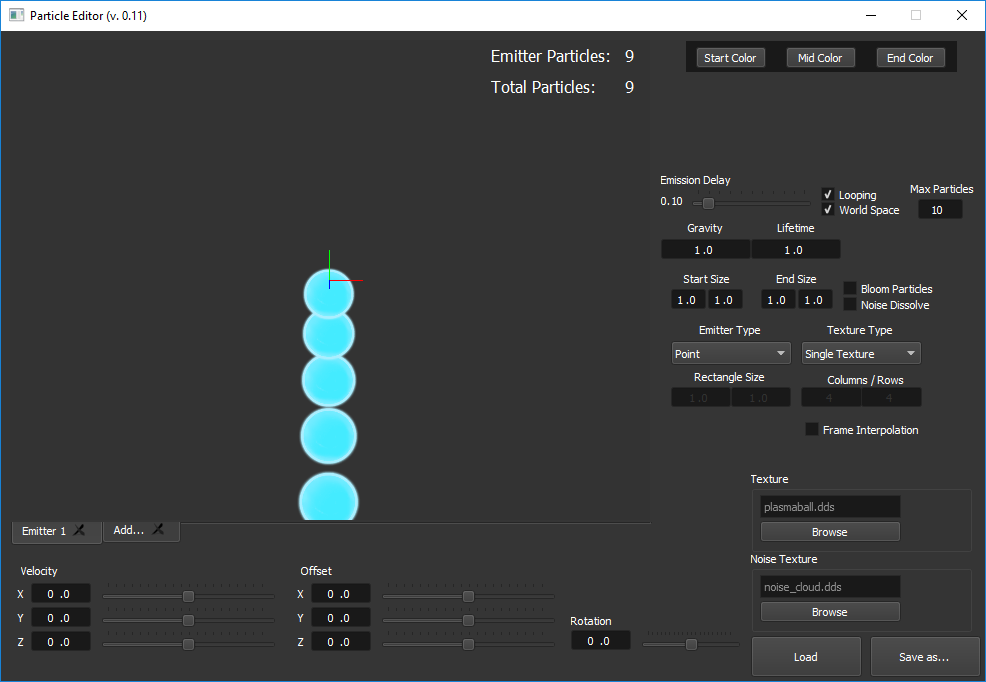

PARTICLE DESIGNER 1 SKIN

They enter and exit the cleanroom through airlocks, air showers and/or gowning rooms, and they must wear special clothing designed to trap contaminants that are naturally generated by skin and the body.ĭepending on the room classification or function, personnel gowning may be as limited as lab coats and hairnets, or as extensive as fully enveloped in multiple layered bunny suits with self contained breathing apparatus.Ĭleanroom clothing is used to prevent substances from being released off the wearer's body and contaminating the environment. Personnel selected to work in cleanrooms undergo extensive training in contamination control theory. All of the air delivered to a cleanroom passes through HEPA filters, and in some cases where stringent cleanliness performance is necessary, Ultra Low Particulate Air (ULPA) filters are used. The key component is the High Efficiency Particulate Air (HEPA) filter that is used to trap particles that are 0.3 micron and larger in size. They vary in size and complexity, and are used extensively in industries such as semiconductor manufacturing, pharmaceuticals, biotech, medical device and life sciences, as well as critical process manufacturing common in aerospace, optics, military and Department of Energy.Ī cleanroom is any given contained space where provisions are made to reduce particulate contamination and control other environmental parameters such as temperature, humidity and pressure. Cleanrooms are used in practically every industry where small particles can adversely affect the manufacturing process.

0 kommentar(er)

0 kommentar(er)